FIBROTEC HARDWARE

FIBROTEC

FIBROTEC is a range of hardware made from highly resistant and functional fibre. Its design shows concern for aesthetics, but also for the functionality of the doors. Durable and resistant, this hardware are able to withstand high weights.

With FIBROTEC hardware, DOORGATE sets itself apart from national and international sectional door manufacturers, positioning itself among the leading manufacturers in the development of improvements for garage doors. In such a competitive market where every detail counts, the use of this hardware allows our customers, in the installation market, to obtain a category of differentiation and a qualitative perception of their proposals – providing a final added value.

FIBROTEC RANGE OF HARDWARE

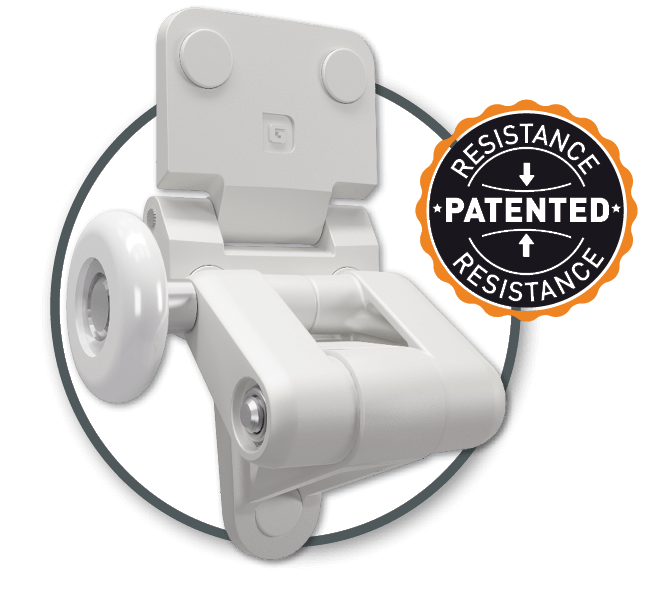

DOUBLE ROLLERS SUPPORT

SINGLE ROLLERS SUPPORT

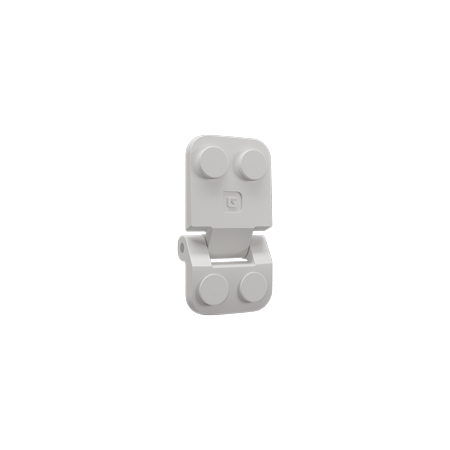

HINGE

SIDE HINGE

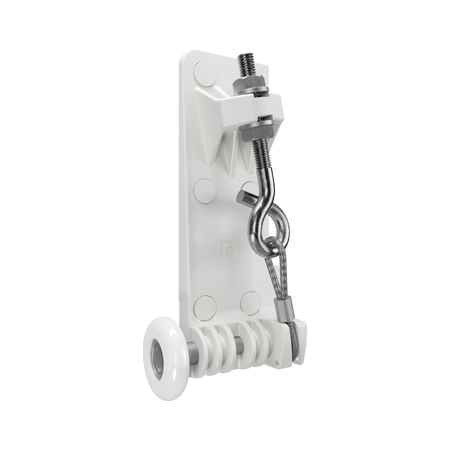

CABLE SUPPORT

SERVICE DOOR HINGE

WHY CHOOSE FIBROTEC SECTIONAL DOORS HARDWARE?

5-YEAR WARRANTY

DOORGATE offers a 5-year guarantee on the purchase of residential sectional doors fitted with FIBROTEC hardware. This guarantee reflects confidence in the quality and durability of FIBROTEC, ensuring that any manufacturing defects will be repaired or replaced at no extra cost to the user.

PANTENTED SYSTEM

The FIBROTEC range of hardware has been developed in a highly resistant fibre and subjected to laboratory tests that have demonstrated its ability to withstand high weights. This system has been patented by DOORGATE!

LESS FRICTION

FIBROTEC hardware has a smoother surface with a lower coefficient of friction than metal hardware. This means that when operating the door, the components that come into contact with the hardware suffer less resistance, resulting in:

SMOOTH RUNNING

The door moves easily and linearly, requiring less effort when operating the door.

REDUCED MECHANICAL WEAR

With less friction during movement, there is a reduction in resistance between the components in contact, which reduces frictional wear.

VIBRATION ABSORPTION

FIBROTEC is able to absorb part of the vibrations generated during the movement of the door, unlike metals, which tend to amplify these vibrations.

NOISE REDUCTION

By eliminating contact between metal surfaces, the door’s operating noise is drastically reduced, resulting in smoother, quieter movement.

EASY TO INSTALL

Installing sectional doors with FIBROTEC hardware offers greater advantages over conventional hardware, making the process easier and more efficient. Installation is simple without the need for complex equipment, reducing installation and parameterisation time.

SIMPLE AND EFFECTIVE FIXING

Fastening systems that are more intuitive and faster than conventional systems, require fewer accessories and less time. Self-drilling hardware and screws speed up the process.

LESS EFFORT DURING INSTALLATION

The design of this hardware, particularly their lightness, contributes to easier handling which reduces physical effort and fatigue during operations.

SPEED OF INSTALLATION

Lightweight and easy to adjust, the time taken to align, fix and adjust FIBROTEC is reduced, which is especially advantageous in large-scale projects where several sectional doors need to be installed in a short period of time.

REDUCING COSTS

The installer’s work is more agile and with fewer resources allocated – fewer professionals and no special equipment for operations – it saves time and costs.

CERTIFIED MATERIALS AND EXCELLENT FINISHES

Using quality, certified materials, FIBROTEC hardware is developed according to a set of rules that guarantee a sublime end product. The excellent finishes reflect the extreme care taken in designing the FIBROTEC range.

PROVEN RESISTANCE

The fibre composite from which the hardware is made is highly resistant, proven in the laboratory to withstand repeated loads and movements even under high pressure.

HIGH DURABILITY

Less prone to deformation and with less wear, FIBROTEC maintains its structural integrity over time, offering a much longer service life than conventional hardware.

LESS MAINTENANCE

Immune to oxidation and with greater protection against corrosion, this hardware requires less maintenance and does not need the lubricants or protective coatings that metal hardware does.

EXCLUSIVE DESIGN

The finishes on the hardware and its design reveal aesthetic concerns, projecting a modern, elegant and exclusive image, contributing to the aesthetics of the door and the general architecture of the rooms, enhancing them.